Receive our news

Subscribe to our monthly newsletter

In the first part of our article, we introduced what an EMS is, and showed how it can impact your channel management and marketing mix, particularly in terms of the "place" aspect of the 4Ps.

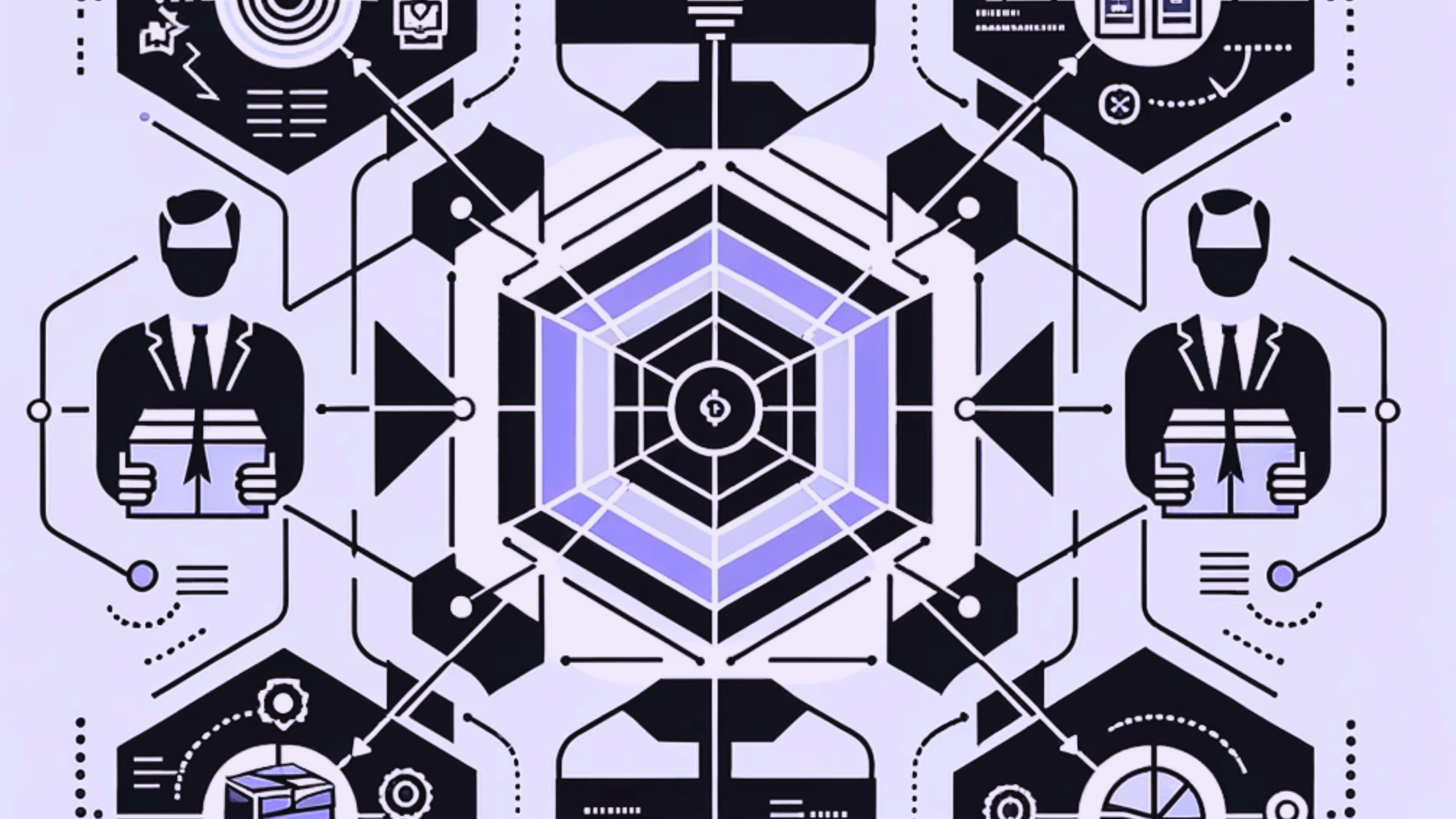

In this first part we have shown that Strategic Market Units (SMU) have become essential elements for brands seeking to optimize their distribution while offering added value to their customers.

In this second part, we'll explore how you can effectively integrate EMS into your existing production and marketing processes to support your channel management.

Whenever possible, favor direct EMS production or sourcing. Work closely with suppliers to ensure compliance with specifications and regulations, just as you do with the rest of your products.

The process must start with a thorough design phase, followed by rigorous production and extensive quality control. Make sure you establish clear agreements with suppliers to guarantee a smooth supply chain, in the same way as you already do on other product lines.

Even if it's not yet a product in your permanent range.

If direct production is not feasible, you can propose alternatives such as changing packaging or creating product bundles.

Coordinate these changes with suppliers, if possible, so as to minimize disruption to the production, storage and marketing processes that follow.

Before creating your products, make sure you integrate them into your information system (ERP / WMS). Develop clear procedures (if you haven't already done so) for :

For outgoing flows, we recommend setting up a supply chain specifically for EMS, for better control of these references in distribution. After all, that's the whole point of setting up an EMS: control.

This involves taking into account the specific characteristics of EMS, which may include but are not limited to:

Strategic Market Units (SMUs), optimally integrated into existing logistics operations, play a crucial role in channel management.

As with all your other product lines, this involves :

The aim is to contribute to more efficient distribution and greater customer satisfaction.

Over-packaging means paying special attention to packaging and the number of products that can be sold per order, adding potentially additional differentiation to the core product, which can be beneficial for channel management.

This over-conditioning can allow :

Accurate labeling: To ensure that you are tracking your Strategic Market Units (SMU) effectively, adopt an accurate labeling approach. This practice, essential for all your products, is particularly important for SMUs, strengthening logistics management and the transmission of crucial information to consumers.

Each unit must be fitted with detailed labels, in addition to an EAN 13 barcode, clearly highlighting the product and its specific characteristics, which is essential for channel management. These labels play a central role in smooth supply chain management, providing crucial information and ensuring regulatory compliance. In addition, they remain a strategic component for marketing communications, informing consumers about the legal aspects of the product while highlighting its benefits.

The importance of labeling is not limited to individual products. In the case of bundles and over-packaging, this practice must be applied with equivalent precision to facilitate channel management. Each element of the bundle must be clearly identified, and details of over-packaging must be explicitly included in the labeling.

Wherever possible, avoid storing EMS by creating additional locations. Use solutions such as Fulfillment by Amazon (FBA) to outsource storage, or 3PLs specialized to your dsitributon channel.

This approach reduces the costs associated with warehouse expansion and inventory management, while guaranteeing rapid product availability to meet demand and test products on the market.

Don't hesitate to combine a product in an SMU to add value (different formats, different colors, etc.).

Using RFID for tracking: To improve the accuracy of EMS product tracking, the use of technologies such as RFID is an idea. RFID (Radio-Frequency Identification) assigns a unique identifier to each product, facilitating automated tracking throughout the supply chain. This reduces the risk of errors, speeds up inventory management processes, and provides real-time visibility on the location and status of EMS products. By integrating these technologies, EMS companies enhance the security of their supply chain, protect their products and optimize operational management.

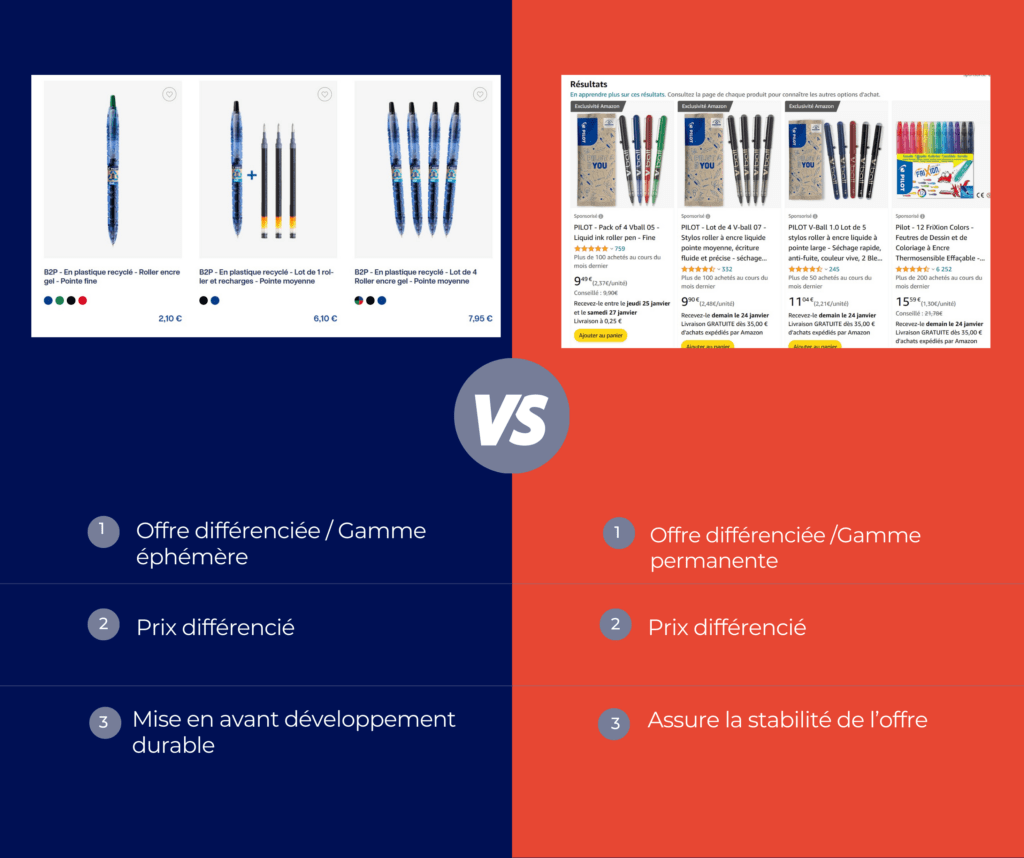

Bundles :

Bundles represent added value, bringing together complementary products to offer a richer, more advantageous shopping experience.

Value creation :

Value Proposition: Create bundles by combining complementary products for an attractive value proposition.

Pricing strategy: Use bundles for an advantageous pricing strategy, encouraging customers to opt for bundled offers.

In conclusion, the successful adoption of Strategic Market Units (SMU) in your production and marketing processes represents a strategic pivot for brands seeking to better optimize and control their distribution and offer a differentiated value proposition.

In this in-depth exploration, we have identified several key steps to effectively integrate EMS, from supply chain to marketing.

The first part of our article highlighted the growing importance of EMS in the marketing mix, particularly in the "place" dimension.

In this second part, we have detailed specific recommendations for maximizing the benefits of EMS in your existing operations.

By implementing practices such as direct production, minimal modification, IT integration, the creation of specific supply chains, and logistics optimization, you can leverage the strategic advantages of EMS.

Special attention to over-packaging, precise labeling and opportunities for permanent, ephemeral and bundled ranges will help strengthen your market position.

In short, by transforming EMS into a key element of your offering, you can not only respond to changing market demands, but also build a lasting, consistent brand image.

Integrating EMS wisely into your existing processes represents a strategic opportunity to thrive in a dynamic and demanding business landscape.